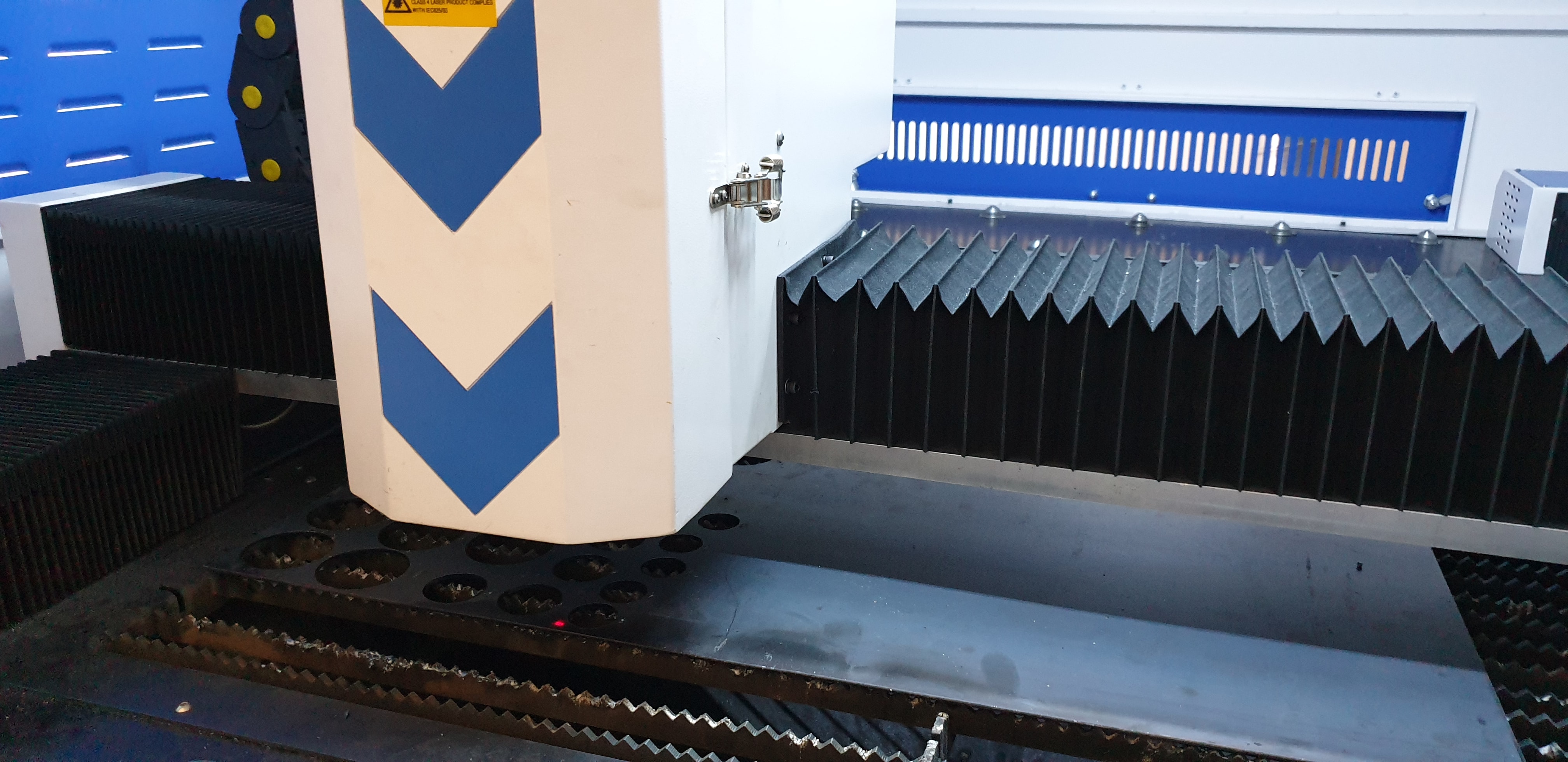

Precision laser cutting

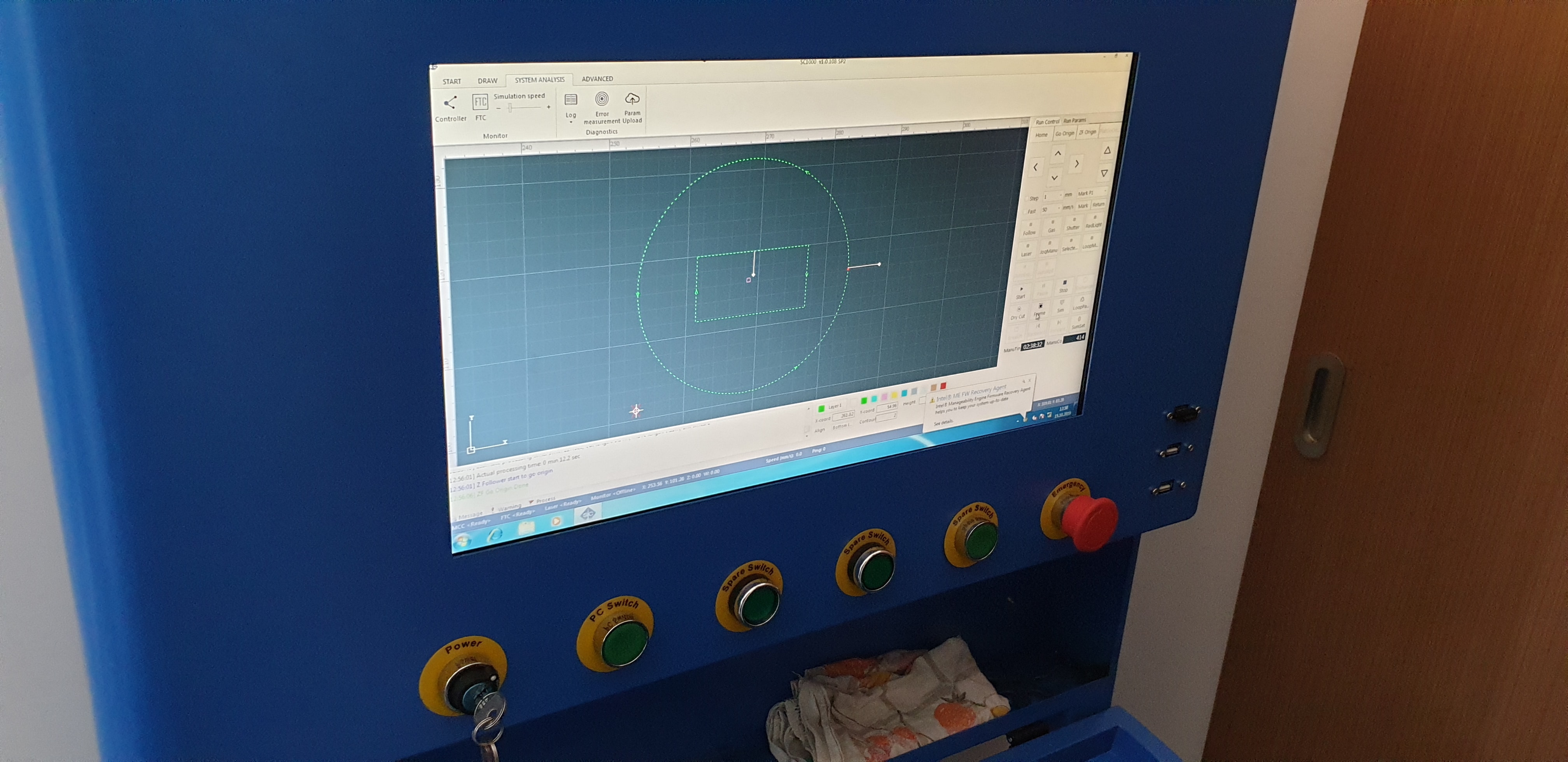

We laser the highest precision in high-speed.

Laser fine-cutting enables punch-like speeds to become reality in the thin sheet metal sector – and without any tooling costs.

Cutting precision we are offering is 50um.

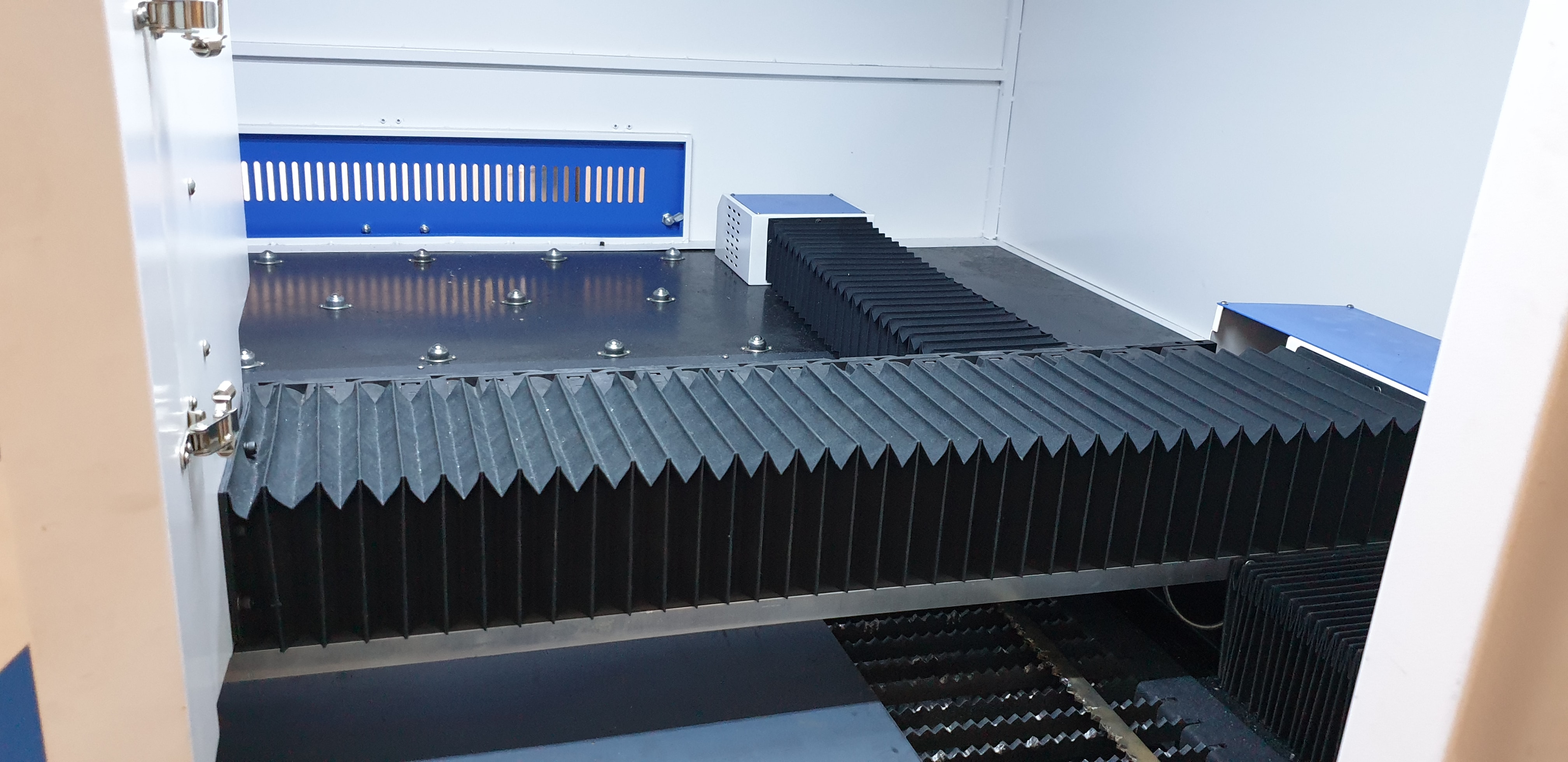

Our system has a linear drive. This allows us to guarantee this accuracy even for larger series.

Due to very narrow kerfs of 0.1mm we cut very filigree, even the finest boards and plugs with our laser.